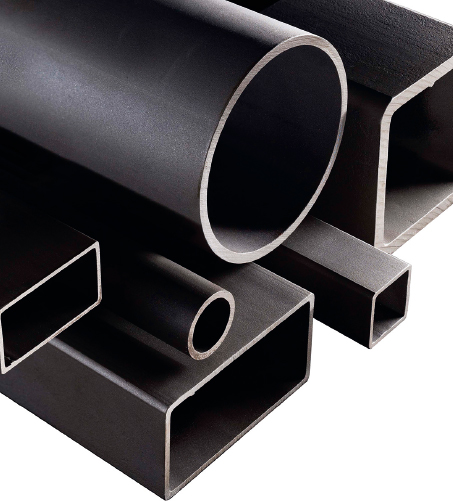

Description

a) Steel hollow profiles

© Images of models and drawings by Andrew Watts and Howard Tee

| Density mild steel | 7840 kg/m3 (490 lb/ft3) |

| Design strength | from 275 N/mm2 to 900 N/mm2 (from 5.7 × 106 to 18.8 × 106 lbf/ft2) |

| Young’s modulus | 210 kN/mm2 (4.4 × 109 lbf/ft2) |

| Coefficient of thermal expansion | 11 × 10-6 K-1 (6.1 × 10-6 OF-1) |

| Thermal conductivity | 45 W/m°C (26 BTU/hr.ft.OF) |

| Specific heat capacity | 480 J/kg°C (0.11 BTU/lb OF) |

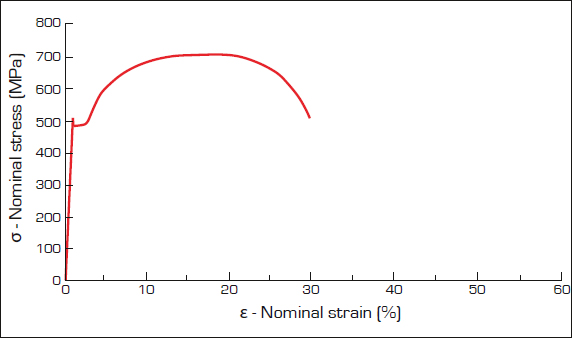

b) Properties and data of structural carbon steels

c) Medium carbon steel stress-strain graph

© Images of models and drawings by Andrew Watts and Howard Tee

Cast iron and wrought iron were the forerunners of steel. Cast iron, a brittle material with high compressive strength, came into general use as a building material at the end of the 18th century, while wrought iron was developed some 50 years later. Wrought iron is a more ductile material and has greater tensile strength, making it less susceptible to shock damage. By the end of the 19th century, both materials had been superseded by steel [a] [b] [c]. Steel was first produced around 1740, but was not available in large quantities until Bessemer invented his converter in 1856. This device introduced a method of blasting air into the furnace (hence ‘last furnace’) to burn away the impurities that inhibited the extraction of a purer iron. By 1840, standard shapes in wrought iron, mainly rolled flat sections, tees and angles were available which could be fabricated into structural components, which are then assembled by riveting them together.

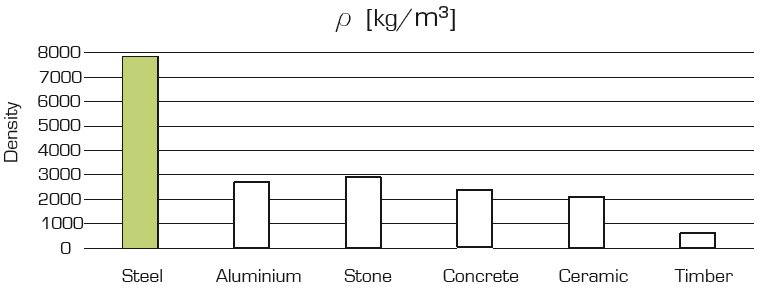

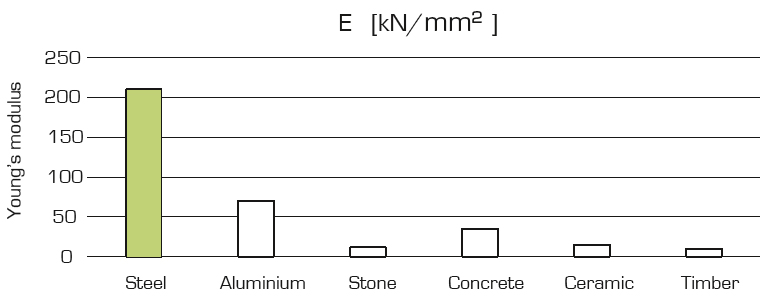

Comparison with other materials; general properties

In comparison with other materials, steels have the following general properties:

- High ductility

[c] , deforming long before they fail. - Lighter than an equivalent structural member in reinforced concrete

[d] . - High stiffness

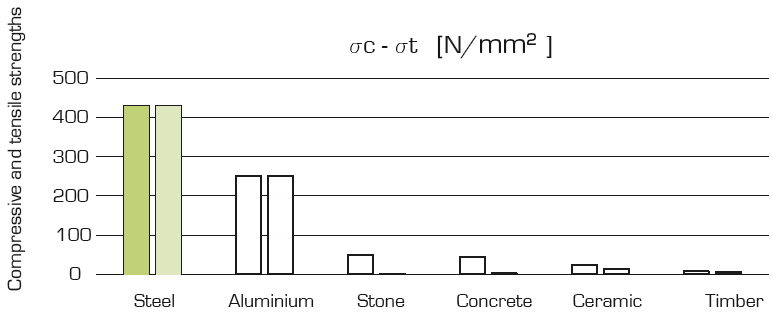

[e] . High rigidity in both tension and compression. - High strength in both tension and compression

[f] [k] . - Appearance is smooth in sheet form; rougher of texture in rolled sections and castings, even with paint applied.

- High impact resistance.

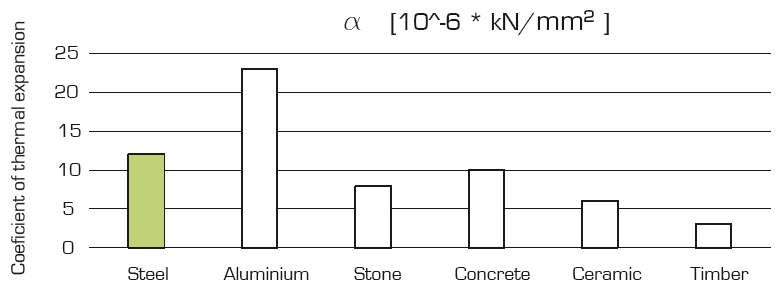

- Thermal expansion approximately half that of aluminium

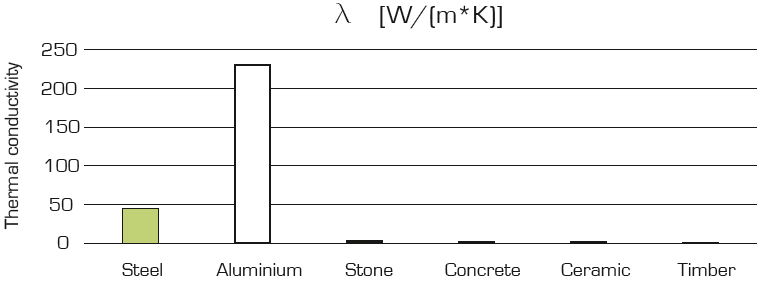

[g] . - High thermal conductivity

[h] . - High electrical conductivity.

- Susceptibility to continuous rusting, excluding weathering steels.

- Low fire resistance.

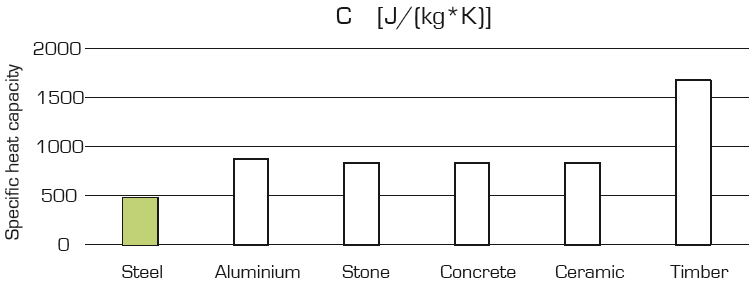

- Low specific heat

[j] .

d) Materials density comparison

© Images of models and drawings by Andrew Watts and Howard Tee

e) Materials Young’s modulus comparison

© Images of models and drawings by Andrew Watts and Howard Tee

f) Materials tensile and compressive strength comparison

© Images of models and drawings by Andrew Watts and Howard Tee

g) Materials coefficient of thermal expansion comparison

© Images of models and drawings by Andrew Watts and Howard Tee

h) Materials thermal conductivity comparison

© Images of models and drawings by Andrew Watts and Howard Tee

i) Materials specific heat comparison

© Images of models and drawings by Andrew Watts and Howard Tee

| Standard | Steel grade | Nominal thickness of element t [mm] | |||

| t ≤ 40 mm | 40 mm < t ≤ 80 mm | ||||

| fy [N/m2] | fu [N/mm2] | fy [N/mm2] | fu [N/mm2] | ||

| EN 10025-2 | S 275 | 235 | 360 | 215 | 360 |

| S 275 | 275 | 430 | 255 | 410 | |

| S 355 | 355 | 490 | 335 | 470 | |

| S 450 | 440 | 550 | 410 | 550 | |

| EN 10025-3 | S 275 N/NL | 275 | 390 | 255 | 370 |

| S 355 N/NL | 355 | 490 | 335 | 470 | |

| S 420 N/NL | 420 | 520 | 390 | 520 | |

| S 460 N/NL | 460 | 540 | 430 | 540 | |

| EN 10025-4 | S 275 M/ML | 275 | 370 | 255 | 360 |

| S 355 M/ML | 355 | 470 | 335 | 450 | |

| S 420 M/ML | 420 | 520 | 390 | 500 | |

| S 460 M/ML | 460 | 540 | 430 | 530 | |

| EN 10025-5 | S 235 W | 235 | 360 | 215 | 340 |

| S 355 W | 355 | 490 | 335 | 490 | |

| EN 10025-6 | S 460 Q/QL/QL1 | 460 | 570 | 440 | 550 |

k) Characteristic values for medium carbon steel

Originally published in: Andrew Watts, Modern Construction Handbook, 6th ed., Birkhäuser, 2023.