Description

- Timber: Overview

- Timber: Production

- Timber: Derivative products

- Timber: Performance

- Timber: Applications

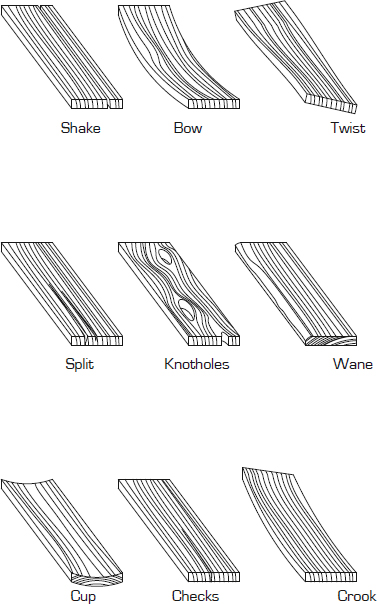

a) Timber defects

© Images of models and drawings by Andrew Watts and Howard Tee

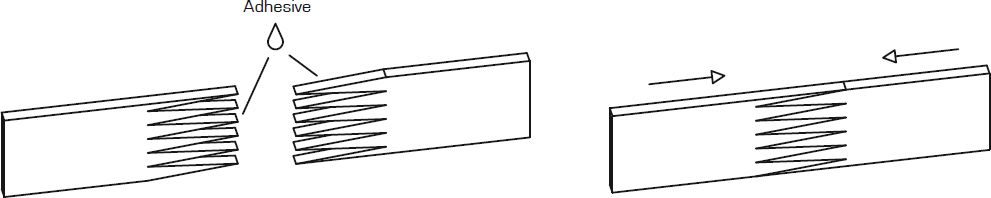

b) Impregnation in a vacuum chamber

© Courtesy of Newtecnic Ltd.

Defects

Timber is dried carefully in order to avoid the effects of crook, split, twist, cup, or bow that may result from the drying out process being uneven [a].

Naturally occurring defects appearing in wood consist mainly of shakes and knots. Knots occur where branches were located in the tree from which the timber was cut, and leave a distinct pattern in the cut timber. They can weaken the timber structurally, and when dried, they may fall out, leaving a knot hole. Other defects, like wane, may result from errors in the cutting or processing of the raw material.

When timber is exposed to moist conditions, it is usually ventilated naturally in order to avoid degradation by rot.

Protection

There is a big variety of protective products for timber. Impregnating the outer zones of timber with preservative chemicals will prevent the wood from rotting or infestation, but some of the chemicals used for this purpose can harm the natural environment if they are allowed to leach into the ground. Impregnation is typically done in a vacuum pressure process [b]. Timber with a moisture content of less than 30% is placed in a vacuum chamber. The air is pumped out of the chamber and the preservative solution under huge pressure is forced deep into the wood. Glued laminated timber is very durable. The oldest, still-standing documented examples were constructed 150 years ago. There are also many examples from around 1950 of glulam structures in their modern form, using synthetic resin adhesives.

Fire resistance

Although timber is combustible, it burns relatively slowly and is often able to retain its structural properties during fire for longer than an equivalent steel structure. When a heavy timber element is exposed to high temperatures, it ignites as it reaches the burning point, which is usually about 300°C, depending mostly on the timber species. When the timber is on fire, a layer of char forms on the surface and protects the core of a member, since char has low conductivity. Underneath the char, there is a pyrolysis zone, which is a layer of heated wood that has been affected by heat. In this shallow layer, the wood is irreversibly decomposed in a chemical sense. The core of the timber member is affected, reducing its structural strength as a result of moisture loss,.

Lighter timber structures are protected with fire retardants, since the thickness of their constituent members is not usually sufficient to resist the effects of fire. Fire retardants are applied directly onto the surface or in a vacuum pressure process. Their main purpose is to create a physical barrier to the flame spread. There are also intumescent coatings used which react to temperature increase, forming an expanded layer of insulation around the timber in the event of fire.

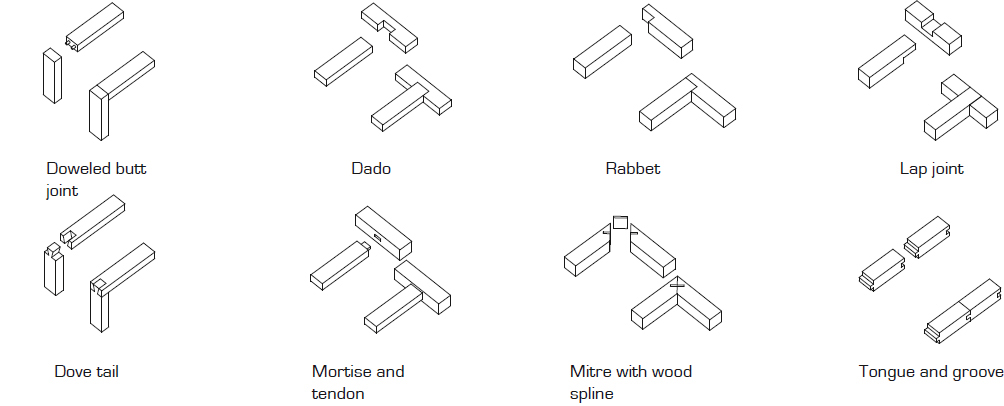

c) Finger joint

© Images of models and drawings by Andrew Watts and Howard Tee

d) Glulam production process

© Images of models and drawings by Andrew Watts and Howard Tee

Originally published in: Andrew Watts, Modern Construction Handbook, 6th ed., Birkhäuser, 2023.